Leviton Poll

Volume 16 | Issue 4 | 2025

Leviton Builds What’s Next for Hyperscale and AI Data Centers

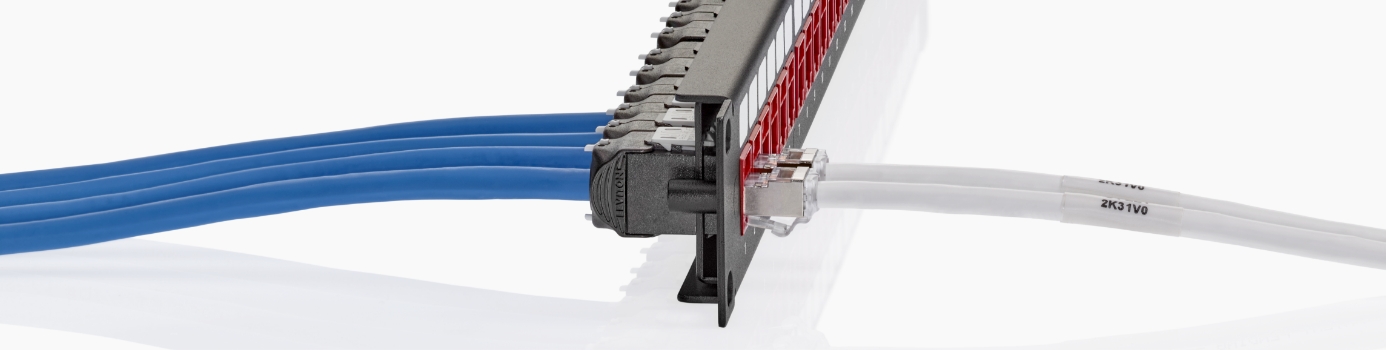

Demand for artificial intelligence (AI), high-performance computing (HPC), and cloud computing are fueling a surge in data center growth. However, such data centers require significantly higher network speeds and density than traditional data center networks. This necessitates changes in cabling infrastructure as a baseline — but to truly minimize time to revenue generation, organizations will also need to partner with providers that can ensure timely delivery, rapidly resolve problems, and be an active part of a responsive, agile supply chain.

Leviton Network Solutions has experience serving hyperscale and AI customers, and we have introduced new fiber optic cabling and connectivity solutions specially designed for these highly customized high-density networks.

Structured Cabling for Greater Density and Faster AI Network Deployment

Leviton is well positioned to support unique AI environments with our new STRATA™ product family. The new high-fiber-count STRATA ecosystem includes:

- STRATA IDX Enclosures with capacity for 6,912 fibers for splicing or interconnect

- Regional availability for customized cabinet solutions supporting more than 40,000 fibers

- New high density fiber patch panels offering 3,456 fibers in one rack unit using 16-fiber very small form factor MMC connectivity

- New high count fiber assemblies, array cords, harnesses, and adapter plates using very small form factor MMC connectivity

- New Mass Connect System for rapid deployment of AI and machine learning fiber networks

Leviton has five fiber optic factory sites strategically located around the world that are certified by US Conec to manufacture assemblies with MMC connectivity, ensuring product availability and support for large scaling initiatives.

Cabling and Connectivity for Immersion Cooling

Cabling and Connectivity for Immersion Cooling

As hyperscale and AI data center operators explore immersion cooling to reduce energy and water consumption, Leviton is helping customers stay ahead of the curve. TORRENT™ immersion-ready copper and fiber solutions extend the performance of Leviton solutions in liquid-cooled environments for AI servers and HPC systems. These solutions have been tested and found to be acceptable per the OCP Materials Compatibility in Immersion Cooling, Rev 1.0 requirements. Additionally, jacket and insulation materials retained 80% or more of Tensile Strength & Elongation when tested per ASTM D412 after being aged for 14 days at 80 °C.

In addition, in June 2025, Cisco and Leviton announced an alliance for AI-ready data centers. As a Cisco Engineering Alliance Partner, Leviton collaborates with other solution providers to advance standardized, scalable systems in immersive cooling environments for AI workloads.

Ensuring Success When Building What’s Next

AI and hyperscale network operators need manufacturing partners with expertise in the latest networking architectures, physical layer infrastructure and data center facility design. Manufacturers should have in-house experts to advise on network design, program management and solutions that integrate redundancy, modularity and customization. Leviton has expanded its team of data center design engineers to support optimal network plans, conceptual drawings, diagrams, and more for our hyperscale or AI data center customer. This team includes experts who are NVIDIA-Certified Associates in AI Infrastructure and Operations. The team works hand-in-hand with Leviton’s comprehensive customer support staff, which includes customer service, tech support, specifications services, applications engineering and more — headed by a central point of contact.

Complex and large-scale data center networks require agile, responsive partners with the ability to scale, who can provide assurance of product quality, performance, and on-time deployment. Leviton is ready to help build what’s next.

Learn more about our solutions for AI and hyperscale data centers at Leviton.com/AInetworks.

Subscribe Today

Like what you’re reading? Get more industry news and trends in our quarterly newsletter when it’s hot off the press.

What fiber mode are you using or considering in your AI data center network?

Reliable Network Performance Past the Outer Limits

Extended distance is a strategic necessity in modern network planning. With an explosion in the number of devices requiring connectivity, alongside expansion in the size of enterprise environments, both indoors and out, enterprise networks increasingly need to go further. Let’s break down how to design a system that is scalable, agile, and delivers assured performance.

Assess Your Networking Needs

When designing an extended distance network, there are a few key considerations that must be front-of-mind. Extended distance designs:

- Must function in the installation environment where the devices are located

- Need to work across all network topologies

- Require an application warranty from the manufacturer to ensure full support

These three guiding principles define a successful extended distance network connection. Regardless of whether you’re using external devices like IP Security cameras and card readers, or providing the connectivity for an outdoor Wireless Access Point, you must ensure your infrastructure can meet these requirements at a distance beyond 100 meters. This is typically achieved with one or two main design choices:

- Category cabling designed for extended distances

- Network channel extenders

Category Cabling

Structured cabling systems designed for extended distances, like our ATLAS-X1™ SST MILLENNIUM™ copper system, has many advantages. It allows for diverse link combinations to achieve connectivity across complex network coverage areas, has interoperable components that permit easy repairs and replacements, and can easily be reconfigured to meet new challenges. The latter is perhaps most important, as structured cabling offers a built-in application upgrade path that helps with continuity of service and eases equipment upgrades. Moreover, category-rated solutions can be used throughout the entire network design, not just for extended lengths: this simplifies your bill of materials and can reduce time spent on the job site.

However, it’s critical that when implementing structured cabling for extended distances, you review the manufacturer’s performance warranty closely. This allows you to evaluate the claims made by the manufacturer regarding extended distance, and get a full picture of the system’s capabilities.

Network Channel Extenders

In areas where category cables won’t reach or where dedicated power is limited, network channel extender systems, like Leviton’s OneReach™ solution, offer an alternative. While installation is more complex, and environmental considerations are even more important, the flexible, highly-configurable nature of these modular systems is useful for many applications, especially in large buildings and outdoor spaces.

Go Beyond 100 Meters With Us

As an end-to-end global network solutions provider, Leviton is always looking for ways to provide scalable, dependable systems that address end-user needs; both now and in the future. Our global ATLAS-X1 SST MILLENNIUM system now supports longer, warrantied four (4) connector channel distances, thermal cycled to 60° C (140° F) with 1000BASE-T and Type 1 PoE out to 155 meters (508 feet). The system also supports 2.5 Gbps to 140 meters (459 ft) and 5 Gbps to 110 meters (360 ft) while providing support for PoE up to 100 Watts. By combining fiber for long-distance data transmission and copper conductors for Power over Ethernet (PoE) delivery, the North American OneReach Network Extender System can support remote devices inside and outside buildings with Gigabit Ethernet up to 3,048 m (10,000 ft).

For more information about these systems, please visit leviton.com/atlas-sst and leviton.com/onereach.

News You Can Use

Tech Tips: The SDX Advantage

Why use our SDX Splice Modules?

Fiber splice modules eliminate the need for individual splice trays within a fiber enclosure and provide better organization and slack management of fibers. Designed to be used with our OPT-X™ SDX Patching Platform, Leviton’s OPT-X SDX LC, SC, and MPO Splice Modules protect and organize fusion spliced fibers (up to 12, 24, or 72 fibers) for installation in an SDX fiber enclosure or panel. The modular design enables faster field splicing and simple management of pigtails within the housing.

Additionally, our SDX Splice Modules provide the following benefits:

- Our patented MPO ribbon pigtail assembly allows for easy routing within the module and mass fusion splicing with no preparation

- Our patented internal shutters on LC adapters eliminate the need for dust plugs, reducing waste and protecting users from harmful laser exposure

- Integrated latching tabs allow for one-handed insertion and removal from enclosures and panels

- Universal splice holder that accommodates ribbon and single fiber splice sleeves

- A clear cover is included on the module, providing visibility of fiber routing and splicing workmanship

- Shipped in sustainably smart cardboard and paper packaging that is entirely recyclable and contains no single-use plastics

Our SDX Splice Modules are part of the OPT-X™ SDX Premises Fiber System, a globally available end-to-end system that includes Leviton Premises Distribution tight buffer and ADVENTUM™ loose tube fiber cables. For more on the OPT-X family of systems, visit leviton.com/optx.

Ask the Experts

Q: How do I test multifiber channels?

A: First, let’s make sure you have what you need. For Tier 1 testing, which is required per industry standards, an Optical Loss Test Set (OLTS) is needed. The tester will need to measure loss and length and validate polarity to meet the Tier 1 requirement. OTDRs (optical time-domain reflectometers) do not meet this requirement. Each OLTS consists of a main and remote unit, each with an integrated source and power meter. Once setup to test, the OLTS provides an automated pass/fail against ANSI/TIA, ISO, or custom limits.

If using a duplex OLTS, some additional steps and testing components are required. Temporary MPO/MTP to LC breakout harnesses and a 3-jumper reference are required to perform MPO link testing with a duplex OLTS.

As always, inspect and clean all connector end faces during the reference setup process and as you continue to test. Below are the basic steps for testing an MPO/MTP link with a duplex OLTS.

Step 1: Begin by setting a 1-Jumper reference per your tester’s required procedure. Once complete, the main and remote units will both be setup with a launch and receive test cord.

Step 2: Setup the automated test function by selecting fiber type, choosing the connector or module losses, and selecting the 3-jumper reference.

Step 3: Perform a 3-jumper reference, by adding a temporary duplex patch-cord between the remote and main test cords. This will reference out the duplex connection points, ensuring that when the temporary harness is swapped in only the MPO/MTP connections will be measured.

Step 4: Remove the temporary LC patch cord and replace with the temporary MPO to LC Breakout harnesses. Connect each tester unit by connecting the duplex test cords to the LC end of the harness.

Step 5: Connect the MPO/MTP side of the harness to the MPO/MTP link under test.

Step 6: Perform testing of each two-fiber pair by moving the test cords to each LC pair in the harness. Once complete, move on to the next MTP/MPO link.

Learn more about MPO connectors in our white paper MPO Connector Basics and Best Practices.