Leviton Poll

Volume 16 | Issue 2 | 2025

Structured Cabling: The Backbone of Tomorrow's AI Networks

Investments in Artificial Intelligence (AI) have skyrocketed, and AI computing clusters are at the beginning of a huge ramp in growth. Data center managers face a range of challenges when deploying AI, including power, cooling, and latency, and must rapidly adopt new technologies to meet those challenges. AI is also driving higher and higher data rates in data centers. Today, 200 Gb/s is most likely the slowest data rate in a large-scale AI cluster. In fact, 400 Gb/s and 800 Gb/s are more typical, and 1.6 Tb/s is expected to gain adoption in the near future.

There are a wide variety of options when it comes to AI network hardware and configurations. However, the NVIDIA DGX H100 and latest DGX B200 are currently the most popular AI server platforms. Structured cabling provides connectivity to four core network functions that interface on the rear of these NVIDIA DGX servers.

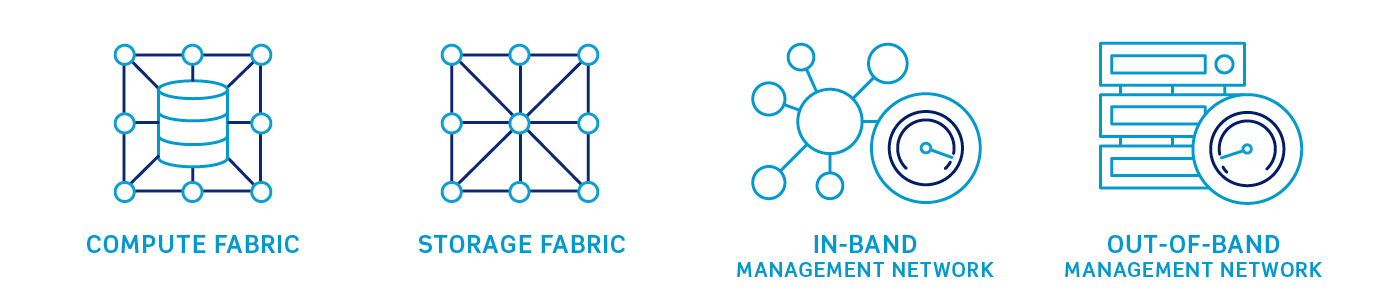

COMPUTE FABRIC

Highest bandwidth connections enabling communication between GPUs across nodes to act as a large supercomputer for intense AI training and learning.

STORAGE FABRIC

Provides ready access to shared data across the nodes in support of the training and learning functions.

IN-BAND MANAGEMENT NETWORK

High-speed links for connecting all services that manage the AI cluster.

OUT-OF-BAND MANAGEMENT NETWORK

Low-speed copper connections for other basic management functions, connects to servers, switches, PDUs, etc.

As an example, in a DGX H100 reference architecture, each server has 4 twin MPO ports for a total of 8 MPOs and up to 64 fibers for the compute function. Depending on the device configuration, there are also 1 or 2 ports used for the storage and in-band network for a total of 10 to 12 MPO interfaces and as many as 96 fibers per system. There is also a copper interface for the out-of-band management, which must be considered when planning the cabling infrastructure.

Structured Cabling vs. Direct Attach Connections

One option for connecting such a high volume of fiber between the AI systems and switching fabric is to install port-to-port direct connections, using either Active Optical Cables (AOCs) or individual 8-fiber MPO array cords. While relatively straightforward, this does create significant cable volume in the cable tray and within the racks themselves. When using AOCs, pulling the transceivers through the pathways can be cumbersome and the installer has to be very careful to avoid damage. Specific labeling on these cables is critical and a level of bundling or grouping of these cables is highly recommended to help ensure the source and destination devices are known to help the installer.

As an alternative to direct connections, structured cabling offers significant benefits in AI clusters. This design replaces the vast number of point-to-point connections in the overhead tray with patch panels on either end and higher fiber count MPO trunk cabling between the racks. The approach allows for smaller in-rack cables on the front side of patch panels.

Additionally, a structured cabling design:

- Reduces congestion and improves cable density within the rack. Structured cabling allows for shorter array cords or breakout legs of a harness or trunk, using 2.0 mm diameter cable for a 33% size reduction compared to AOCs and traditional array cords.

- Improves airflow. Less in-rack congestion due to the smaller diameter cabling contributes to better airflow for a positive effect on power and cooling.

- Improves deployment speed. Pre-terminated trunk cables can be pre-installed so that only patch cords need to be run to the active equipment on the day of turn-up.

- Adds flexibility to help installers with cable management, offering panel labeling, easy cable grouping, and color coding of ports and connectors.

- Has virtually no impact on latency and operates well within link loss budgets. With cabling, the key parameter for latency is not the physical optical connections but the overall length of the channel. Properly designed structured cabling will not add additional latency compared to AOC or direct cabling connections.

There are a variety of different AI system configurations and ways that AI networks and the associated cabling infrastructure can be assembled. Leviton has a full suite of products available to support these network with our set of OPT-X™ Global Fiber Systems. Additionally, our data center design team partners with customers to create efficient, cost-effective network infrastructure designs built to handle tomorrow’s challenges.

Learn more about Leviton’s data center solutions.

Subscribe Today

Like what you’re reading? Get more industry news and trends in our quarterly newsletter when it’s hot off the press.

Do you plan on using a structured cabling network architecture in your AI data center project(s)?

Network Solutions' Fuquay-Varina Expansion Cuts Time-to-Value for Global Customers

Leviton Network Solutions recently announced completion of the $25 million expansion project in its Fuquay-Varina, NC manufacturing facility.

The project, started in 2022, more than doubles the size of the facility, expanding the 55,000 sq ft facility by an additional 94,000 sq ft. In addition to being a significant investment into the local area of Fuquay-Varina, this construction will greatly enhance Network Solutions’ ability to support global demand.

The Fuquay-Varina site manufactures a variety of multimode and single-mode cabling products used to connect local area networks in a variety of applications including commercial enterprises, data centers, industrial and harsh environments. Pre-expansion, the Fuquay-Varina facility produced record volumes of optical fiber; 2025 and beyond, the expansion will unlock even greater production capability for Leviton, as it has scaled up the facility’s optical fiber cabling and MTO assembly production as well as engineering and product testing capabilities.

Leviton expects global demand for fiber cabling systems to grow in conjunction with the adoption of AI across industries. More than doubling the size of the North Carolina factory not only develops its capacity to support US-based customers but also unlocks a greater degree of supply chain redundancy for global customers. The expanded facility will facilitate Leviton’s mission of shortening time-to-value for global customers, providing additional capacity and cutting lead times —all while investing in the local community of Fuquay-Varina.

Leviton held a ribbon cutting event on April 9, 2025, to celebrate this milestone achievement with company executives, local government officials, and Leviton’s local employees. Blake Massengill, mayor of Fuquay-Varina, attended the company’s ribbon cutting event and said, “The Town of Fuquay-Varina is grateful for Leviton’s commitment to investing in our region, which will have far-reaching benefits not only for the local economy but also for the state as a whole.”

“Leviton is a global company that chose Fuquay-Varina — with its highly skilled workforce and business-friendly environment — as the site to manufacture fiber optic cabling to support IT networks in the US and throughout the world. We thank Leviton for their investment into the region and we look forward to building a long-lasting partnership with the company.”

Learn more information about Leviton’s global fiber optic cabling systems.

News You Can Use

Tech Tips: Unlock Extended Distance

Outdoor and indoor/outdoor (I/O) cables are designed to be smaller, lighter, and more flexible but require some minor additional precautions to prevent water ingress during the cable pulling operation. I/O cables also provide the benefit of not needing to transition to an indoor rated cable which can provide significant savings on materials and labor.

Gel-Free Outdoor and I/O Cable Products:

Protect Cable Ends During Installation: Use heat shrink tubing and vinyl electrical tape to prevent water ingress.

Routing: Suitable for underground conduits, and short outdoor runs within the building footprint. If the cable features a flame rating (e.g., plenum), then the cable can continue from the wet location into other building spaces without a transition point. The cable jacket must remain unabraded (no holes or cuts) to prevent water ingress, which can negatively impact performance.

Water Exposure: Not designed for direct burial or standing water. Ensure conduits are designed to drain water.

Connection Points: Use appropriately sized cable clamps and suitably rated enclosures for external wall mounting. Drip loops should be used to prevent water infiltration into the building or device.

Explore our outdoor cable offering.

Gel-filled outside plant (OSP) cables offer superior water blocking, making them more suitable for environments with significant water exposure.

Gel-Filled OSP Cable Products:

Routing: Suitable for more rugged environments, including building-to-building interconnections, direct burial, and installations where water exposure is significant. Surge protection may be required per local codes.

Water Exposure: Fully water-blocked with gel, providing enhanced protection against water penetration. If there is a minor disruption to the jacket integrity, water will not be able to propagate through the cable.

Handling: Gel-filled cables require the removal of gel with solvents and swabs prior to termination.

Connection Points: Use appropriately sized cable clamps and suitably rated enclosures for external wall mounting. Drip loops should be used to prevent water infiltration into the building or device.

Product Spotlights

Ask the Experts

Q: A “one-size-fits-all” data center design won’t work for my organization; can I get guidance on how to build a data center that addresses all of my pain points?

A: As data center networks become increasingly complex, organizations need partners that will provide more than cable and connectivity. Our data center design experts work closely with both contractors and customers to understand their needs, provide an optimal plan for deploying structured cabling solutions, and create a complete bill of materials. Working with you from conception to deployment, we’re ready to help through remote or on-site analysis and can deliver custom product designs that meet specific network requirements.