There are three basic approaches to terminating fiber connections in the field: adhesive connection and field polishing, mechanical connectors and no polishing, or fusion splicing using pigtail assemblies. Let’s take a brief look at each.

Field Polish / Adhesive terminations

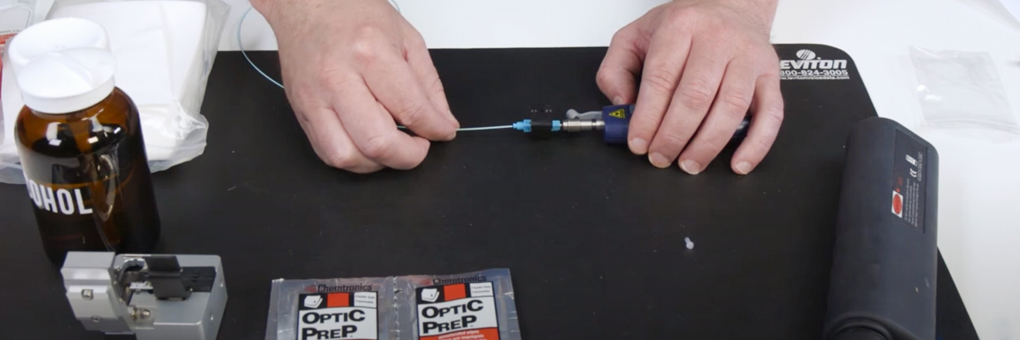

Adhesive connectors are a very common option. With these terminations, a 1- or 2-part system adhesive is injected into the connector, and the fiber is inserted. An accelerator or “primer” can be used to cure the adhesive more rapidly.

Adhesive terminations are the least expensive option. However, they are very craft sensitive, so labor costs are a consideration. Also, a word of caution: The Telecommunications Industry Association (TIA) has tightened its requirements single-mode return loss (reflectance), at 0.35 dB. Meeting those requirements becomes much more challenging with field polish connections. With enterprise networks moving to higher speeds, return loss is now more of a concern than ever. Minimizing return loss requires improving your polishing procedures, or choosing a factory polished connector such as mechanical terminations.